A transparent, verificable and auditable process - Our commitment towards ethical and environmentally low impact activities is traceable and verified by the prestigious certifications:

STeP by Oekotex, Higg and Global Recycled Standard.

Thanks to warp seamless technology we transform all the yarn into a product, reducing waste of cut-sewn garments by up to 30%.

Sustainable Materials - we create innovative products, using the new generation of regenerated ecological textile fibers.

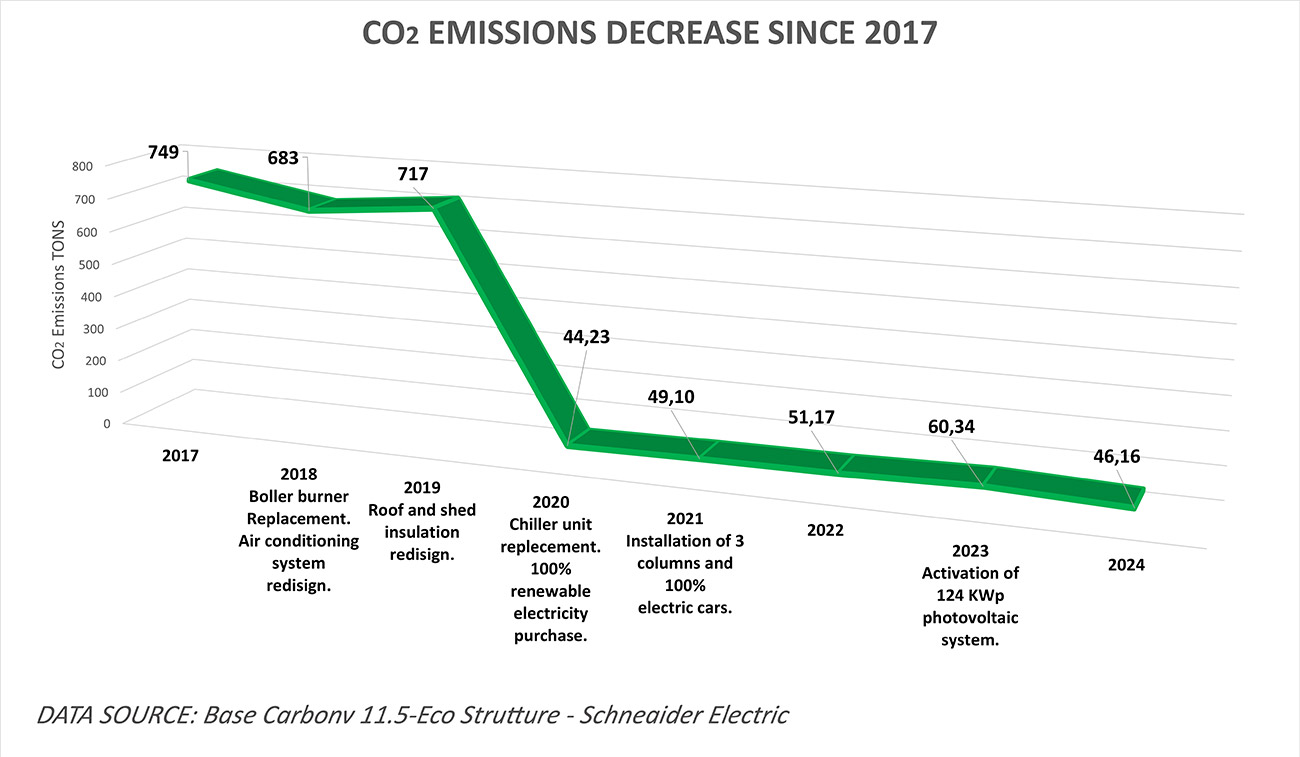

Energy-efficient systems – in the last 4 years thanks to the implementation of our energy systems we have significantly decreased CO2 emissions with a rising trend for coming years.

On Demand manufacturing process - this plays a key role in reducing goods to be disposed of: customers can change anytime which style to order, accordingly to real time selling-out, thus avoiding stock remaining.

Energy-efficient systems: in the last 4 years we have significantly decreased CO2 emissions with a rising trend for coming years.

We have made a big investment to start the realization of a 150kw photovoltaic plant with the project to further enlarge it in the next 3 years.

Our vehicle fleet is emission-free electric.

We respect the environment by using only energy produced from renewable sources such as water, sun, wind and the earth's heat, certified by the "guarantees of origin" system of the energy service manager, according to ec directive 2009/28/ec.

If you want to know everything about our breakthrough technology, you can find out more about 3D knit technology.